Ladder Safety Regulations

Reading time: 9 minutes

What are the ladder safety regulations in the UK?

Ladder and stepladder use is not banned under UK health and safety law, but there are restrictions and guidelines in place to help reduce risks. The right type of ladder must be used, and the user must know how to use it safely. The Health and Safety Executive (HSE) states ‘ladders can be a practical option for low-risk, short-duration tasks, although they should not automatically be your first choice’.

According to HSE guidelines on ladder health and safety, you must:

1. Decide whether a ladder should be used

-

Is it appropriate for the task, or would lower alternative equipment be better?

-

If you’re using the ladder for more than 30 minutes, alternative options are recommended, such as access towers or electric lifts

-

Only use ladders where it’s safe to do so - if the ground is level, no power lines are nearby, the area is cordoned off and the ladder can be secured

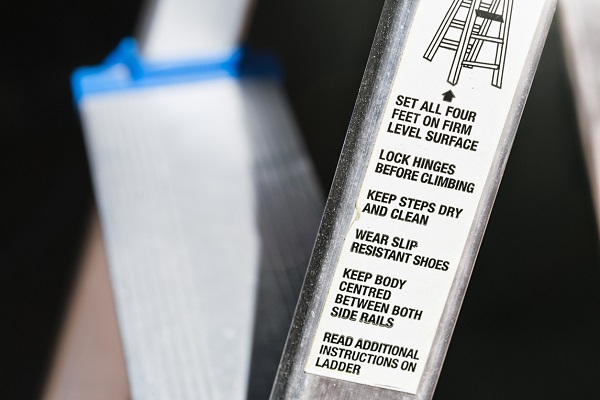

2. Know how to use a ladder safely

-

You must be a ‘competent person’ (or being trained by a competent person)

-

Assess the risks

-

Use the correct ladder for the job

-

Follow the manufacturer’s guidelines

3. Check that the ladder is safe

-

Carry out a ‘pre-use check’ before using the ladder

-

Regularly inspect the ladder for damage

-

Employers must also ensure detailed ladder checks are carried out regularly

Many industries also recommend using ladder safety devices to help minimise slip or tip risk.

Do you need a certificate to use a ladder?

No certificate is needed to use a ladder, either domestically or professionally. However, UK ladder health and safety rules state that you must be competent. A competent person is considered someone who has knowledge, training and practical experience. If you’re being trained, you must be supervised by a competent person at all times when using the ladder.

Are ladder inspections a legal requirement?

Employers have a legal duty to make sure that ladders are safe and inspected regularly, as part of The Work at Height Regulations 2005 - which are designed to prevent avoidable accidents from falls, and these are mandatory in the UK. Ladder inspections can be done by a competent person within the company, and doesn't necessarily have to be done by an external inspector. Any ladder or stepladder being used by employees must be suitable for the job and in good condition. A visual safety inspection must be carried out before use each day. Section 6 of the regulations (ladder requirements) also states the safety requirements for low risk use of ladders at work.

Types of ladders and safety rules

There are 9 ladder types which are used at home or in businesses, with 4 main types used primarily by professionals. Each type demands slightly different safety checks and safe use guidance:

Leaning ladders

Leaning ladders (which can also be an extension ladder type) have to be leaned up against the wall and have two feet. To use them safely, ladder safety rules say you must:

-

Not overload the ladder - only carry light equipment

-

Not over-reach - make sure the ladder is long enough

-

Follow the manufacturer’s instructions on setup and use

-

Use the 4-in-1 rule - (4 units up per 1 unit out) so the ladder is at a 75° angle

-

Don’t work off the top 3 rungs

-

Ensure the base is stable - don’t stand it on movable items such as pallets

-

Avoid holding items when climbing - use a tool belt

-

Don’t work within 6m of overhead power lines

-

Maintain 3 points of contact when climbing (2 feet and 1 hand, or 2 hands and 1 foot at a time)

-

Use a stability device or other safety device

-

Perform pre-use safety checks and visual inspection

Telescopic ladders

Telescopic ladders are similar to leaning ladders, and can also be known as extension ladders, multi-purpose ladders or folding ladders, but they have a specially extending telescopic design to make them longer or shorter. This makes them easier to store and transport, as well as having the ability to extend it more accurately to the height you need. They are also lockable for additional safety. Ladder safety rules state that it’s vital to:

-

Not overload the ladder - as per leaning ladder safety instructions

-

Not over-reach

-

Follow the manufacturer’s instructions on setup and use - especially to avoid trapping fingers when extending the ladder or taking it down

-

Use the 4-in-1 rule (if applicable) - with the ladder at a 75° angle

-

Don’t work off the top 3 rungs

-

Use the locking device correctly

-

Ensure the base is stable

-

Avoid holding items when climbing

-

Don’t work within 6m horizontally of any overhead power lines

-

Maintain three points of contact when climbing

-

Use a stability device, if possible

-

Perform pre-use safety checks and visual inspection - remember these may differ between brands

Stepladders

stepladders (also known as A-frame ladders) have a triangular design, with 4 feet on the ground for increased stability. To ensure stepladder safety, the user must:

-

Ensure all 4 feet are on the ground and the steps are level

-

Not over-reach

-

Follow the manufacturer’s instructions on stepladder safety, setup and use

-

Only carry light tools and materials

-

Use the locking devices correctly

-

Place the ladder so that you face the task - not side on, if possible

-

Prevent tipping over - don’t side load

-

Secure or tie the steps if side loading jobs are unavoidable

-

Maintain three points of contact when climbing

-

Perform pre-use safety checks and visual inspection

Combination and multi-purpose ladders

Combination or multi-purpose ladders can also be a form of extension ladders, stepladders or leaning ladders, but they often have a unique design - such as a particular shape, or separate sections that can be assembled in different ways, for a variety of jobs. Just like other ladder types, you must:

-

Check to ensure that any locking mechanism is properly used

-

Re-check the locking system when the ladder is changed

-

On 3-part combo ladders, never extend the top section beyond the marked limit

-

Ensure all feet are on the ground and the steps are level

-

Not over-reach or overload the ladder

-

Follow the manufacturer’s instructions on setup and use

-

Secure or tie the steps if side loading tasks are unavoidable

-

Maintain three points of contact when climbing

-

Perform pre-use safety checks and visual inspection

Stepladder safety

Although stepladders are great for short tasks at lower heights, when non-heavy tools are needed, they are at risk of tipping over. As well as the usual safety rules, which include pre-use checks and ensuring all 4 feet are on the ground, the user must be aware of side loading and how this can be a risk for tipping over. To prevent this, the ladder can be tied in place, and the user should keep 3 points of contact on the ladder at all times. A barricade should also be put around the worker to stop others from knocking into it.

Ladder safety checklist

Ladders must be inspected regularly - before each use - as well as visually after the ladder is moved using the ladder safety checklist. HSE advises on the following inspections to be carried out, both before the ladder is used and during its use. More detailed inspections will be needed as per each manufacturer’s instructions, which must be recorded and made available to employees.

Ladder pre-checks

-

Employers must make sure pre-checks are done before use

-

Ladders must be suitable for the task and in a safe condition

-

Before using, a competent person must check that there are no visible problems or defects

-

Make sure the ground is stable and the ladder is set up correctly

-

Check that the ladder is strong, secure and the correct size for the job

-

Ensure the manufacturer’s instructions of safe storage and maintenance have been followed

-

Ladders in scaffold systems must be inspected every 7 days under scaffolding inspection requirements

-

Do not use the ladder if any of the above haven’t been met

Ladder checks

When using ladders, look out for any signs of:

-

Damaged or worn feet

-

Twisted, bent or dented stiles

-

Unsafe or damaged locking mechanisms

-

Cracked, bent, worn or loose ladder rungs

-

Missing or damaged tie rods

-

Missing safety instructions

-

Any other visible signs of wear and tear which may cause an accident

Any issues with the ladder should be reported to a senior staff member or your employer. It is also an employer’s responsibility to ensure that ladders are inspected by a competent person.

Ladder safety FAQs

What are the safety procedures for a ladder?

As well as making sure the ladder is safe and right for the task, users must always face the ladder rungs while climbing or descending, never try to move or extend the ladder while standing on it, consider securing the ladder, and never work off the top 3 rungs. Try to make sure that the ladder extends at least 1m above where you’re working.

What are the ladder regulations uk?

In 2018, new ladder regulations for manufacturers were introduced. EN131 is the latest harmonised standard for portable steps and ladders, covering minimum safety requirements, to ensure new ladders are wider, sturdier and stronger. This replaced British Standards BS 2037 and BS 1129 (also known as Class 1 and Class 3 ladders). Always look for the EN131 certification when buying or using a ladder.

What is the 1 in 4 rule for ladders?

The 1-in-4 rule is designed to ensure the ladder angle is in the safest position. The ladder base should be one space out from the wall per 4 spaces up, creating a 75° angle. For example, if the ladder is 4m high, the base should be placed 1 m from the wall (a quarter of the ladder’s height).

Do you have to be qualified to use a ladder?

No certificate is needed to use a ladder, either domestically or professionally. However, UK ladder health and safety rules state that you must be competent. A competent person is considered someone who has knowledge, training and practical experience. If you’re being trained, you must be supervised by a competent person at all times when using the ladder.

Are ladder inspections law?

Employers have a legal duty to make sure that ladders are safe and inspected regularly. This can be done by a competent person within the company, and doesn't necessarily have to be done by an external inspector. Any ladder or stepladder being used by employees must be suitable for the job and in good condition. A visual safety inspection must be carried out before use each day.

Do ladders need a LOLER?

Ladders at work can come under the Lifting Operations and Lifting Equipment Regulations (LOLER), as well as the Provision of Use and Work Equipment Regulations (PUWER) and Regulation 3 of the Management of Health & Safety at Work Regulations. This means ladders must be strong and stable, used only for their intended purpose, used safely by competent people and must be regularly inspected, amongst other requirements.

Disclaimer: The information contained on this page is intended as an overall introduction and is not intended as specific advice from a qualified professional. Travis Perkins aims to avoid, but accepts no liability, in the case that any information stated is out of date.