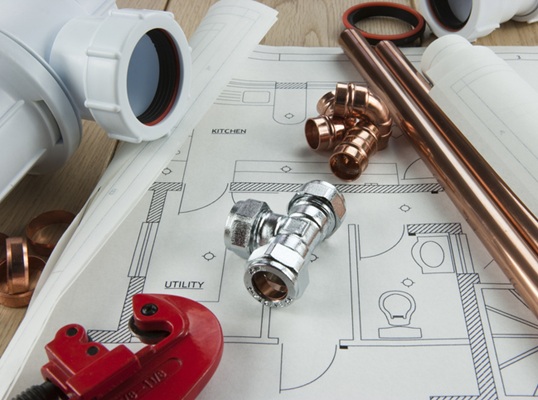

How to Choose Pipe Fittings Correctly Every Time

Reading time: 4 minutes

Compression fittings

Designed with a nut and a compression ring (the latter sometimes referred to as an olive) that work to form a watertight seal, compression fittings are available in various sizes and are known for their reliability.

They are also practical in that heat, soldering or specialised plumbing tools are not required to assemble them onto plumbing systems.

When to use compression fittings

-

Around domestic water systems.

-

On a plumbing job where work is carried out on brass, copper or plastic piping.

When to avoid using compression fittings

-

On high-pressure applications.

-

On high-temperature applications.

-

On plumbing systems which encounter constant movement or vibration.

-

When a permanent soldered joint is required, such as on gas lines.

-

When the water supply passing through the piping might contain additives or chemicals.

End feed fittings

A traditional and reliable choice of plumbing installation, end feed fittings are made up of a copper body and no internal stop. This means that a sturdy and permanent connection can only be achieved when soldering techniques are applied when installing them onto a plumbing system.

Also known as solder fittings, this equipment is available in many different sizes and configurations to suit a huge selection of plumbing installations. Whether you are working on hot or cold systems in commercial or domestic settings, end feed fittings can usually be used.

When to use end feed fittings

-

On a plumbing job where work is carried out on copper piping.

-

On high-pressure applications.

-

On high-temperature applications.

-

Within permanent plumbing systems.

When to avoid using end feed fittings

-

In confined spaces where an open flame could be a fire risk.

-

Within temporary plumbing systems.

MDPE fittings

Short for the robust and durable material Medium Density Polyethylene, MDPE fittings deliver your plumbing projects with fantastic levels of strength and resistance to pressure.

Flexibility is another appealing characteristic of MDPE fittings (along with compatible MDPE pipes), as the equipment can maintain its integrity when met with temperature fluctuations or ground movements.

When to use MDPE fittings

-

On MDPE pipes, often located within underground water supply systems whether in agricultural, domestic or industrial applications.

-

When the water supply passing through the piping might contain additives or chemicals.

When to avoid using MDPE fittings

-

On above-ground water supply systems, unless the material has been made UV-resistant and can be supported to avoid damage or sagging.

Push-fit fittings

As the name suggests, push-fit fittings are designed to push onto a pipe and then lock into place without the need for specialist tools or sealing applications. This makes them ideal when speed and ease of use are important for you and your plumbing jobs.

Once in place, these fittings also use internal seals for a reliable and leak-proof connection within a plumbing system.

When to use push-fit fittings

-

On a plumbing job where work is carried out on copper or plastic piping.

-

On plumbing jobs which take place in tight spaces.

-

Within temporary plumbing systems.

When to avoid using push-fit fittings

-

On high-pressure applications.

-

When you are looking for budget-friendly pipe fittings (push-fit fittings are usually more expensive than other types of fittings).

Solder ring fittings

A durable and long-lasting choice, solder ring fittings feature a pre-applied ring of solder on the inside of the material so that it can create a secure connection with copper piping.

Otherwise known as pre-soldered fittings or Yorkshire fittings, the use of a pre-applied ring of solder means that you only need to heat the fitting with a torch to melt the built-in solder.

By not needing to carry out separate soldering work, installations can be quick and simple to create a reliable seal and robust joints for leak-free connections.

When to use solder ring fittings

-

On high-pressure applications.

-

On high-temperature applications.

-

On a plumbing job where work is carried out on copper piping.

-

When plumbing installations need to achieve a cleaner finish for an aesthetically pleasing design.

-

Within permanent plumbing systems.

When to avoid using solder ring fittings

-

On plumbing jobs which take place in areas near flammable materials.

-

On plumbing jobs which take place in tight spaces.

-

Whenever a temporary fitting is required.

By using this guide and then considering the exact requirements of your next plumbing job – including the material of the pipes involved, the space available, and both the pressure and temperature ratings of a plumbing system – you should have no problem ordering the correct pipe fittings every time.

Don’t forget you can keep improving your plumbing skills too, by browsing through many of the other guides found within our comprehensive home maintenance advice hub.